Automatic drip trays – sometimes known as “Bomb Bay Door” drip trays – can be a very useful option for highly efficient, automated filter press dewatering operations.

The Automated Drip Trays function in a variety of important ways:

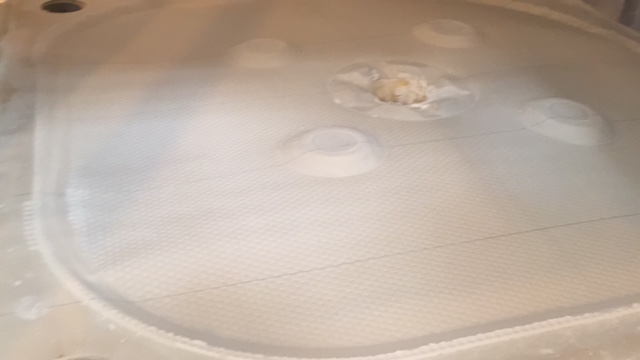

- Collect any dripping filtrate during the feed cycle to prevent drips from reaching the cake conveyors or filter cake dumpsters.

- Capture filtrate residue when the filter closing pressure is initially released, prior to filter cake discharge.

- Allow high pressure wand cleaning of the cloth and/or plate, discharging the cleaning liquor to a trough via the bomb bay doors.

- Retain wash water generated from the automatic cloth washing equipment and prevent it from creating a wetter filter cake. When an automatic cloth washing system is being utilized – as is common with many of today’s filter presses – it is generally helpful for the automated drip trays/bomb bay doors to capture the water coming from the cloth washing to prevent it from going to the filter cake.

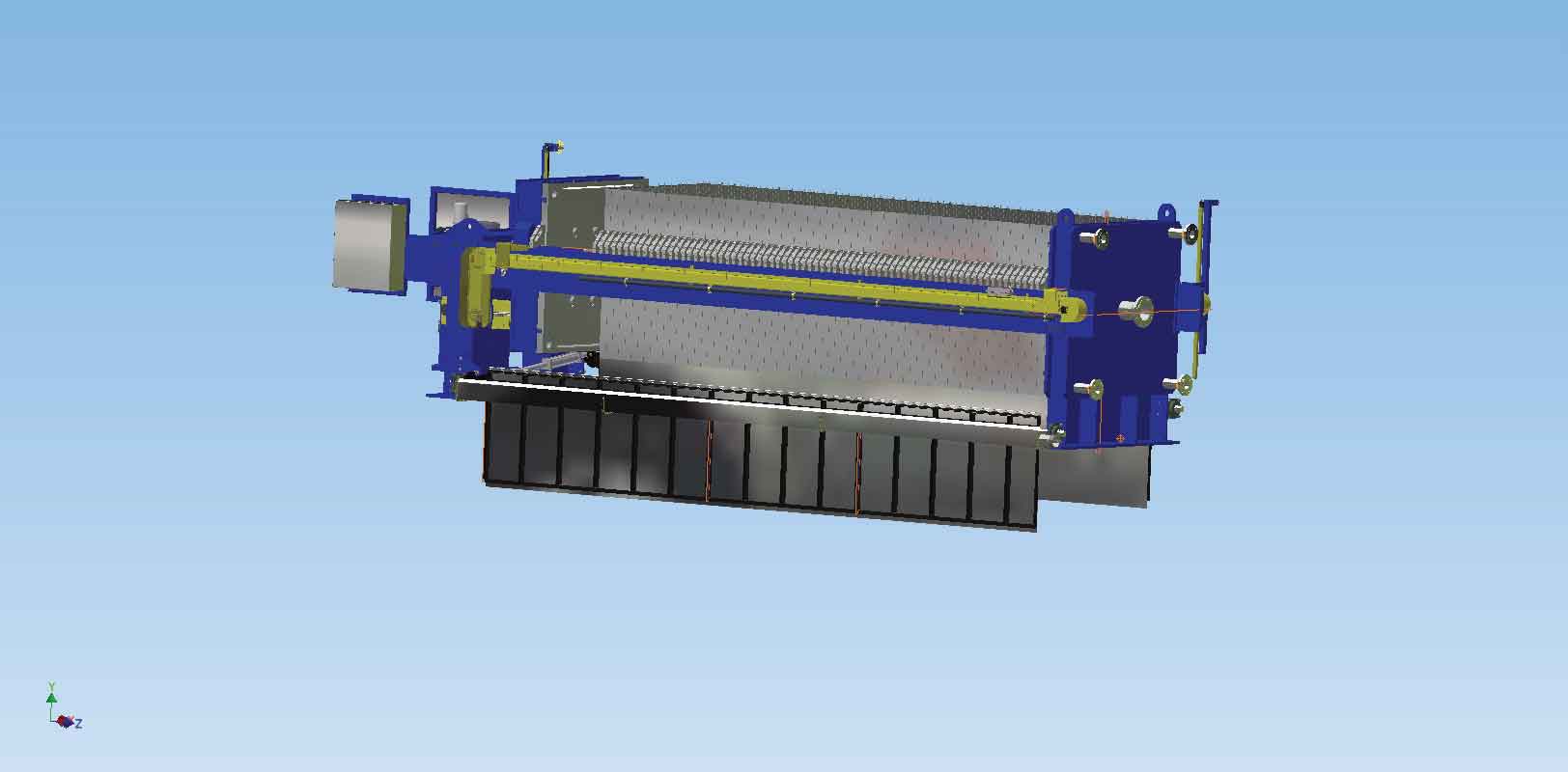

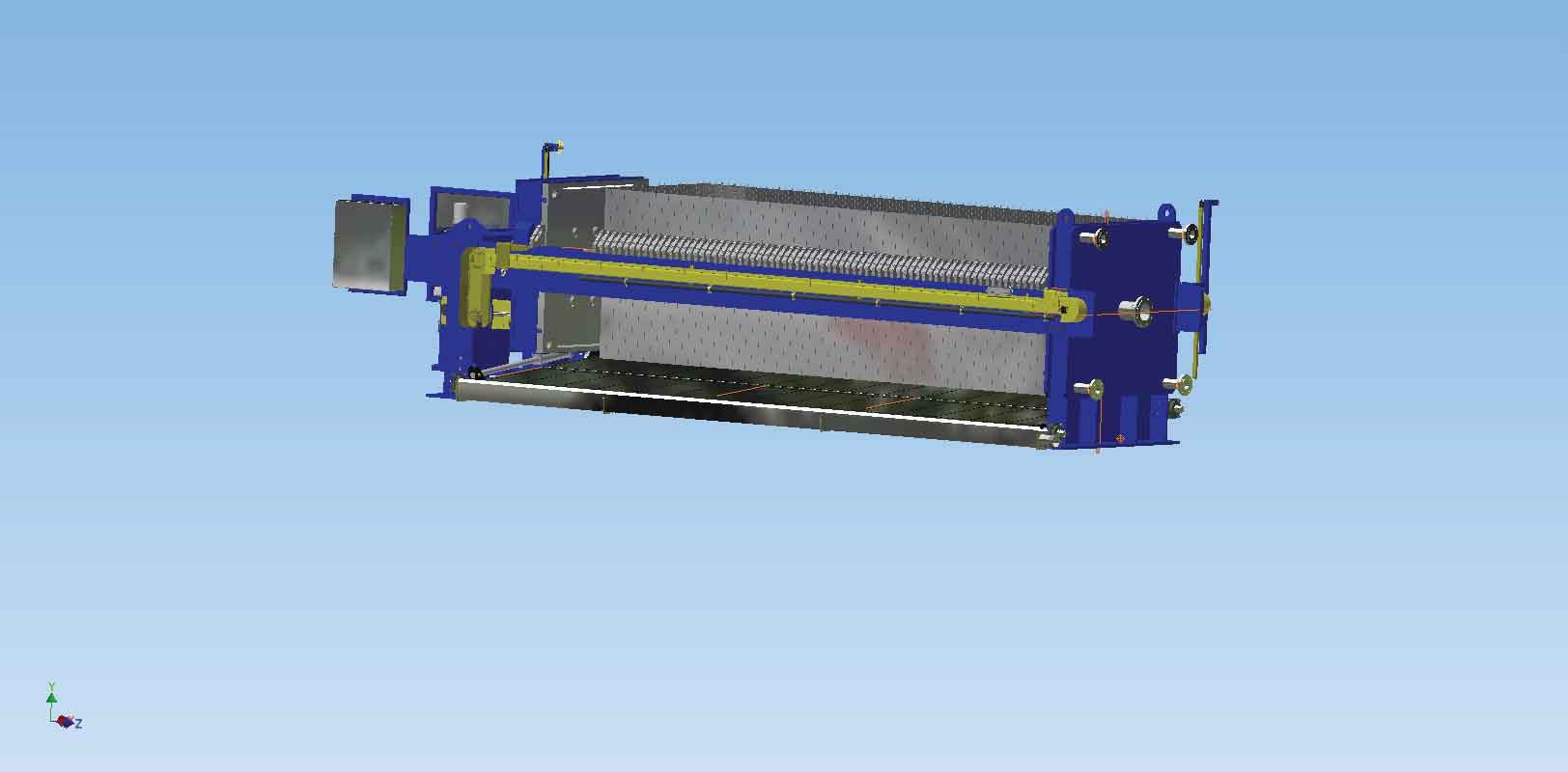

When the drip trays are in the open position, they act as a chute for filter cake discharge.

When the drip trays are in the closed position, this keeps the filter cake that is below the press as dry as possible.

The PLC-controlled filter press can operate the drip trays automatically, as shown in the programmable control panel pictured. A manual override can be utilized for cleaning.

The PLC-controlled filter press can operate the drip trays automatically, as shown in the programmable control panel pictured. A manual override can be utilized for cleaning.

The doors are mounted horizontally and direct the filtrate flow to a trough at one side of the filter press. An inclined trough runs the length of the filter press, collecting and directing the filtrate to a discharge location/connection specified by the customer. Automatic drip trays are typically stainless steel although Micronics has the ability to customize the materials of construction to meet customers’ needs such as utilizing polypropylene and fiber-reinforced plastic (FRP).

Contact us to learn more about our automatic drip trays (and manual drip trays for manual filter presses) and full range of filter press options to help optimize your filter press operation and achieve your production objectives.

The post Automatic Drip Trays and Their Role in Filter Press Operations appeared first on Micronics, Inc.